Steam system treatment

Successful Boiler Water Treatment

Successful boiler operation requires a total system approach to:

- Prepare feedwater before it goes to the boiler

- Protect and keep the internal boiler surfaces clean

- Maximize condensate return

We couldn't find any results for "".

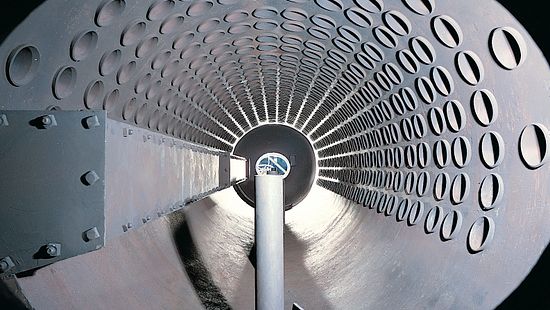

Maximizing Boiler System Performance

We perform detailed system audits and diagnostics to prescribe the best chemical, equipment and service programs to maximize your boiler system performance and efficiency through an effective boiler water treatment program. Through utilizing our innovative programs, we can help you achieve water and energy savings, asset preservation, and increased plant reliability and safety.

Boiler Technology Program Brochure

Nalco Water offers the most comprehensive, industry-leading approach in understanding and analyzing boiler systems, and accurately identifying improvement opportunities to increase competitive advantage. Through our extensive knowledge of the boiler feedwater systems, we know that boiler reliability is critical in the success of refinery operations and are focused on driving boiler system productivity, reliability, and cost savings.